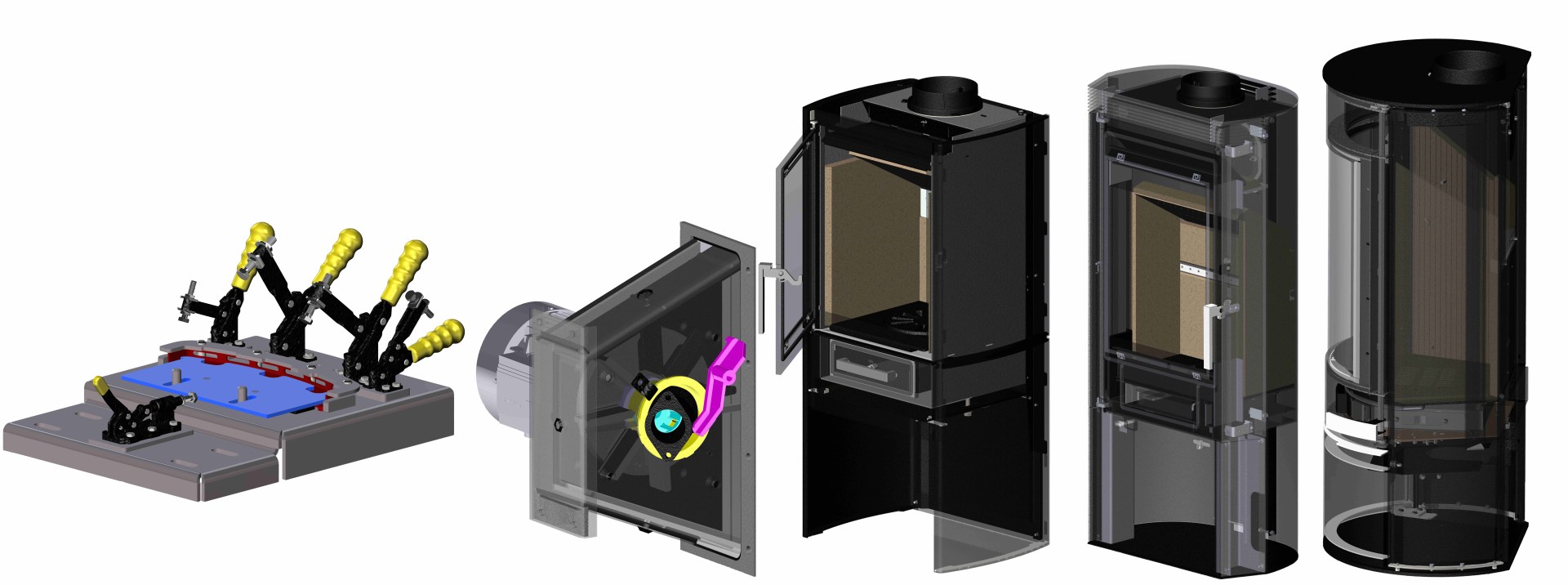

Flow simulation stoves and combustion chambers

Simulation flow of gases and liquids is mainly performed on models of stoves and their combustion chambers. We test and verify our intentions for the construction before the prototype is made.

Custom made simulations are also possible – external, internal, or their combination. Its usage has a wide range: pipes, turbines, fans, cooling, aerodynamic flow, heating, turbulent flow etc. System SolidWorks Flow Simulation is able to do blending and merging of gaseous and liquid substances, including an evaluation of all available variables and information.

We create an exit message that contains the values, graphs, illustrations, animations, and comment for all the simulations.

Flow analysis provides results which we are able to present in numerical terms, but also to create animations and videos that show these data (for the idea here are just basic ones):

• distances for maintaining safe temperatures

• heat and radiation transmission through materials of stoves, or their reflectivity and insulation

• the temperature of the gaseous, liquid substances, also solid parts and their surfaces

• turbulent flow of gaseous substances and whirling for liquid substances

• quantity of gaseous and liquid substances, which flows through the individual sections, penetrations, channels

• density of gaseous and liquid substances of stoves and chambers

• the speed and direction of motion of the gaseous and liquid substances moving in stoves and their chambers

• trajectory (path) of gases and particles moving in stoves and their chambers