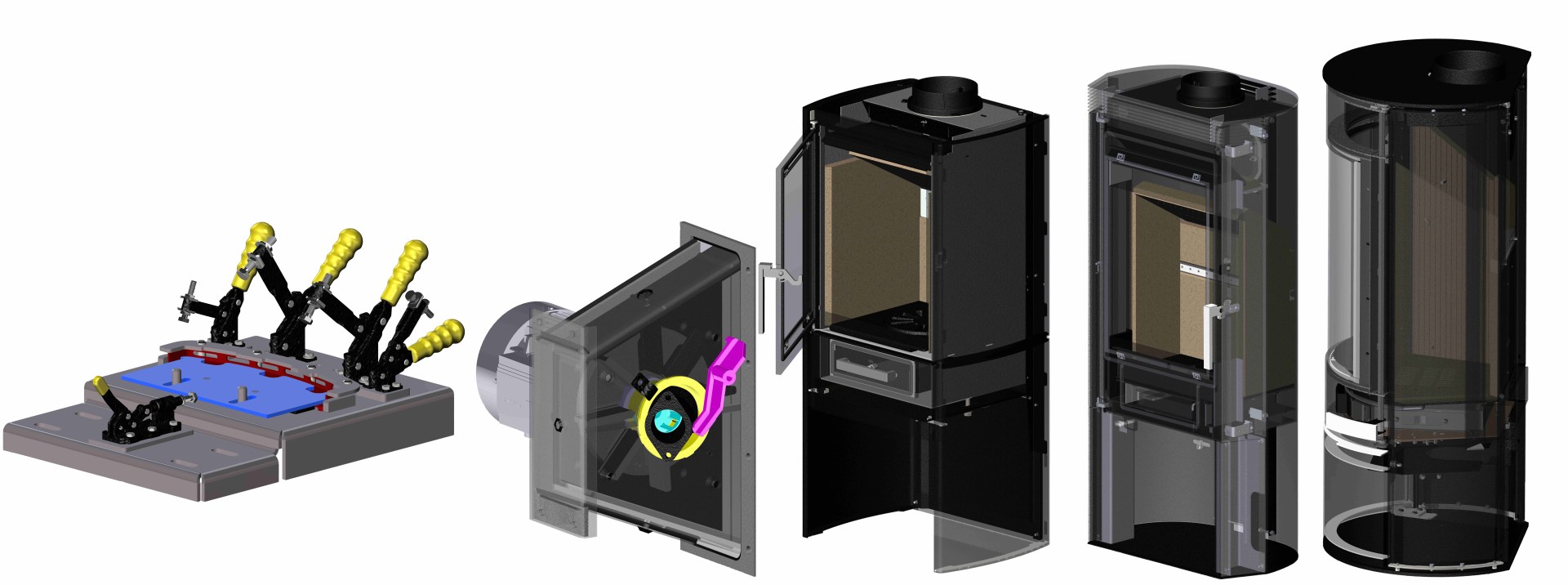

Flow simulation of other parts and components

Custom made simulations are also possible – external, internal, or their combination. Its usage has a wide range: pipes, turbines, fans, cooling, aerodynamic flow, heating, turbulent flow etc. System SolidWorks Flow Simulation is able to do blending and merging of gaseous and liquid substances, including an evaluation of all available variables and information.

We create an exit message that contains the values, graphs, illustrations, animations, and comment for all the simulations.

Flow analysis provides results which we are able to present in numerical terms, but also to create animations and videos that show these data (for the idea here are just basic ones):

• trajectory (path) of gases and particles moving in stoves and their chambers

• the speed and direction of motion of the gaseous and liquid substances moving in stoves and their chambers

• density of gaseous and liquid substances of stoves and chambers

• quantity of gaseous and liquid substances, which flows through the individual sections, penetrations, channels

• turbulent flow of gaseous substances and whirling for liquid substances

• the temperature of the gaseous, liquid substances, also solid parts and their surfaces

· measuring temperatures on modeled sensors can determine an individual temperature on the surface of the parts

• heat and radiation transmission through materials of stoves, or their reflectivity and insulation

• distances for maintaining safe temperatures

SolidWorksFlow Simulation is a powerful tool that can identify problem sites and dificulties during the construction in a wide range of design solutions. It can also confirm or disprove the constructor’s theory before producing a prototype. If you are not able to find an example appropriate to solve your issue, do not hesitate to contact us. The use of the program very extensive.